Direct Screen Printing

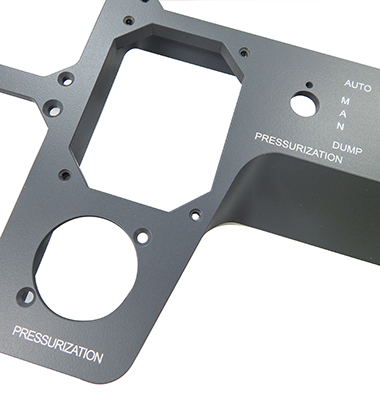

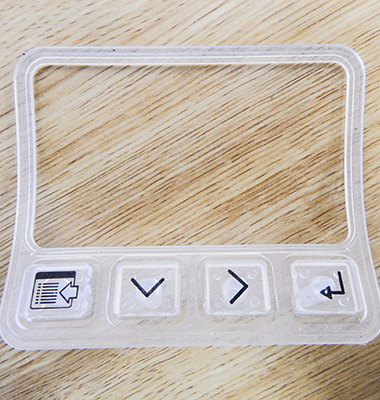

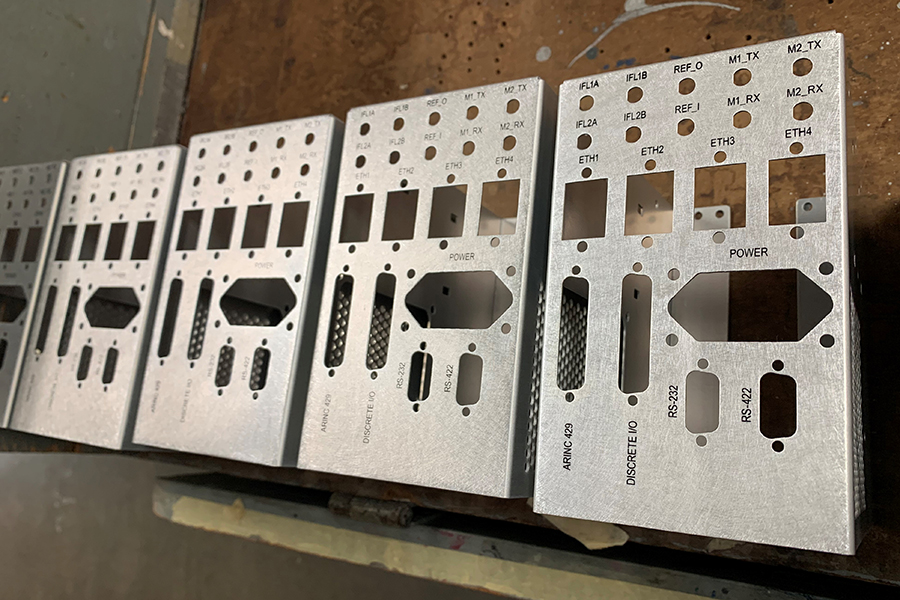

WISPI has many years of experience in direct screen printing on products. Many shapes and sizes on various substrates have been successfully screen printed in our factory. A few examples are, composite airplane dashboards, glass panels, wooden game boards, vinyl tops for medical tables, steel instruction plates and aluminum computer cases.

When tackling a specialty direct screen project, it all about:

- Understanding which ink to use for what substrate

- Fixturing the application to assure consistent coverage and registration

- Deciding which cure method is appropriate for the application, oven cured, UV light cured or Air Dry

The only way to become a true expert in the direct screen-printing process is by experience and repetition……We have both!