News

If you haven’t met us yet…you might not know this but we’re definitely a group of talkers. And if you’re not ready to hit that dial button and give us a call but you still have questions…we’ve taken most of our commonly asked questions and put our answers into the written word. Now…we’re designers and not writers, so we can’t promise these blogs will be as fun as chatting with us, but they will be as informative. Happy reading!

How To Make The Best Hot Fudge Sundae

WISPI Offers Tips to Making the Best Hot Fudge Sundae… Ever Making the best hot fudge sundae hinges on two main things. First, it’s all about the ingredients. Second, it’s about the love and passion that the maker has for the their art of making hot fudge sundaes. WISPI is proud to share our secrets…

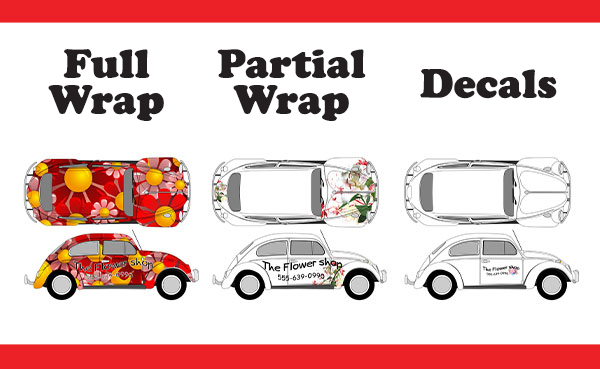

Differences Between Full Vehicle Wrap/Partial Vehicle Wrap/Decals

In a recent request for a customer, I was given the opportunity to design three completely different vehicle graphic variations for a box truck. One included a simple logo and contact information. Another included a small graphic alongside the simple logo and contact information, while the last one consisted of a full graphic incorporating the logo and…

There is no need for a freelance graphic designer when you work with WISPI

We offer free graphic design for customers that partner with us as their full-service graphics manufacturer. WISPI’s professional graphic design team can help create, edit and streamline your graphics, from start to finish. Designing graphics through to the delivery of a finished product, our turnaround time is fast and even faster when we inventory your…

Let’s Talk Equipment Decals…the Heavy-Duty Kind

Equipment decals serve many purposes. They are essential elements of heavy machinery that can identify a manufacturer’s brand, label control panels, and/or contain vital safety information to help reduce risk and liability. But the critical nature of equipment decals can easily become an after-thought among so many other considerations found throughout the manufacturing process –…

Keeping Window or Vehicle Decals Looking their Best

Last week, I received a call regarding the care of vehicle graphics. Since the lifespan of vinyl graphics is affected by exposure to outdoor elements, this is a very important subject. I know it is very unlikely and unimaginable that a vehicle can stay in a protected bubble…all the time, but there are ways to…

Vinyl Truck Wraps: 3 Ways to Improve Your Advertising

Box trucks. Semi-trailers. Branded pickups. Your company may have a range of vehicles within its fleet to haul freight, transport products, or provide added benefits to employees. These primary uses are of utmost importance to the logistics of your business, but could your rugged fleet vehicles actually do even more for your bottom-line? With professionally-designed…

Turnkey Graphics Solutions To Assist Upfitters

Upfitters, graphics, and installationUpfitters are those wizards of transformation that turn ordinary vehicles into highly specialized units ready to help teams become masters of efficiency having all the right tools, equipment and supplies at hand. Much upfitting ensures optimum access to tools and gear inside and outside the vehicle, but for many fleets, customization continues…

Custom Decals, Labels, and Warning Stickers

WISPI provides custom decals for your OEM needs In recent months we’ve found virtual alternatives for many aspects of business, but there’s no virtual substitute when it comes to parts—or labels—that are needed on the production line. Once you start looking for decals and labels, you’ll see them everywhere. On your snowblower, the inside door…

In Need of Quality Vehicle & Fleet Graphic Wraps?

In a recent study by Grand View Research, the number of US marketing dollars being spent on vehicle and fleet graphic wraps continues to climb on a yearly basis – from $1.62 billion in 2015 to an estimated $10.8 billion by 2025. Why spend so much money on vehicle graphic wraps? The short answer is…because…

Head-Turning Results with Reflective Vinyl

Last night, I was stopped at a stoplight on my way back from the grocery store. While I was waiting for the light to turn green, I couldn’t help but notice the vehicles passing by. One of the vehicles stood out; it was a semi. The graphics on the side of the trailer lit up…